With the continuous popularization of new energy and electric vehicles, more and more users are beginning to choose infrastructure charging equipment, and they also need to have a deeper understanding of charging peripheral products. As a manufacturer that has been deeply involved in the charging pile and power conversion industry for many years, infypower will give a brief introduction to the charging pile products today.

Classification of charging piles

Generally, new energy electric vehicles have two charging ports, AC charging and DC charging. The internal car charger is connected to the car charger, and the charger charges the car battery. The DC port is connected to the battery inside, which can directly charge the battery in the car. Therefore, charging piles are divided into AC charging piles and DC charging piles. The DC charging pile is generally a large current, the charging capacity is larger in a short time, the pile body is larger, and the occupied area is large (heat dissipation). It is mostly suitable for fast DC charging of electric buses, minibuses, hybrid buses, electric cars, taxis, construction vehicles, etc. AC charging piles are generally small current, small piles, flexible installation, fully charged in 6-8 hours, suitable for small passenger electric vehicles.

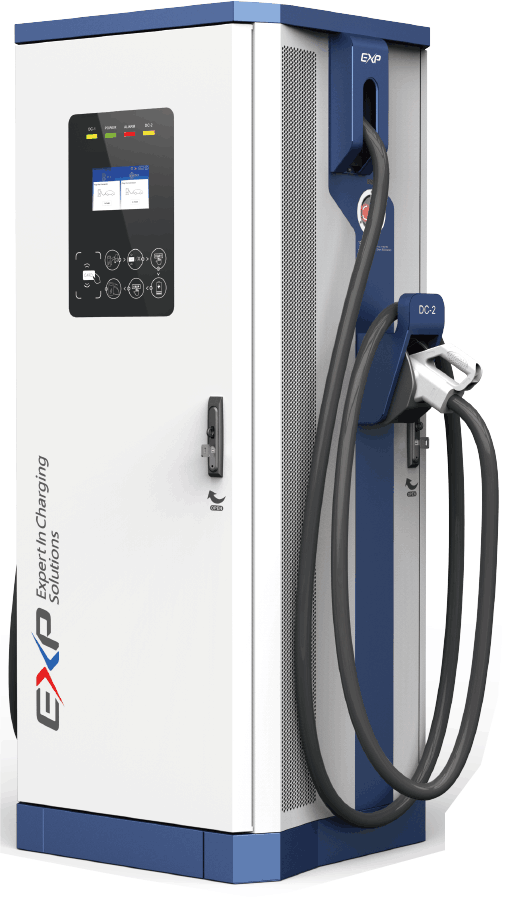

AC piles are divided into wallbox and floor-mounted (classified according to the installer), and DC piles are divided into integrated charger and split charging station (classified according to charging power). According to the classification of charging gun heads: it is divided into AC guns, DC all-in-one single guns, DC all-in-one single guns, and DC all-in-one dual guns.

According to the protection level of the installation site, it is mainly divided into indoor charging piles and outdoor charging piles

Based on the number of charging interfaces, it is mainly divided into charging one vehicle and charging multiple vehicles. At present, the charging piles on the market are mainly of one-to-one charging type. In a large parking lot such as a bus parking lot, multiple charging piles are required to simultaneously support the charging of multiple electric vehicles, which not only speeds up the charging efficiency, but also saves labor.

Charging time

Take a taxi as an example: the battery pack capacity is 80kw.h, and the charging pile power is 120kw with dual guns.

When charging under the mode of simultaneous use of dual guns , a single charging gun is 60kW; 80kw.h÷60kw= 1 hour and 20 minutes;

When charging under the single gun mode , the output is 120kw; 80kw.h÷120kw= 45 minutes.

Whether it is a single charging gun or a dual gun, the charging gun standards of each region need to be considered.

High power charger means faster EV charging?

For example, the battery pack capacity of a new energy vehicle is 60kw.h. The charging time of 80kw pile is about 1 hour, and the charging time of 120kw pile is about 0.8h. In this sense, the higher power of the fast-charging pile, and the higher the charging speed is. But if the power of the charging pile rises to 160kw, the charging time remains still 0.8h. Technically speaking, the charging speed is determined by the battery performance. The battery itself does not reject external charging current and has no control ability. However, high current charging will cause the battery to generate a lot of heat, which will be damaged if it cannot be released in time. Infypower has launched liquid-cooling module and liquid-cooled charging station for professional thermal management. Therefore, increasing the BMS system can effectively control and limit charging in real time. power and current, to achieve the best state. When the charging power is too large and exceeds the limit controlled by the BMS, no matter how large the charging power is, it is invalid.

How many charging ports does a pure electric vehicle have?

Generally, a hybrid passenger car has only one AC charging port, and a pure electric passenger car has two charging ports, one is an AC interface (AC pile ), the other is a DC interface ( DC pile) , and the bus only has a DC port, because DC charging The gun maxes out at 250A, so buses with larger battery packs will have more than one DC charging port.

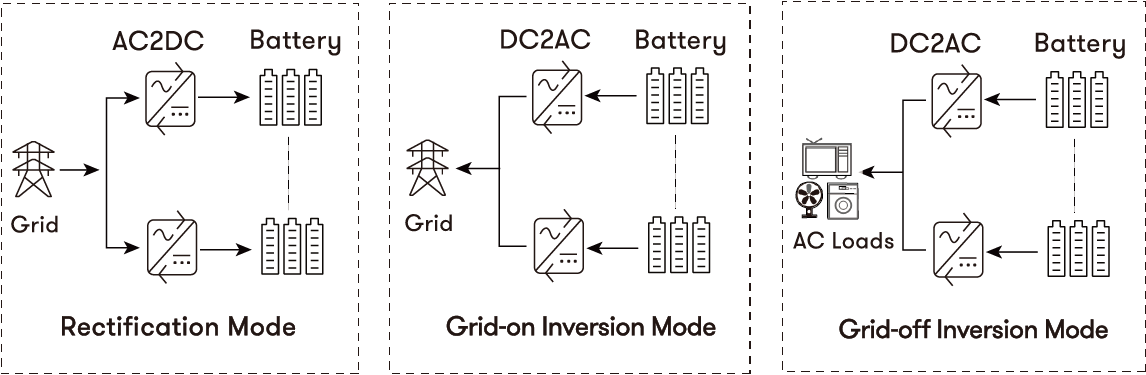

What is the basic principle of new energy charging piles?

The AC pile actually converts the mains (220VAC or 380VAC) into the voltage and power of the set specifications through internal ACDC charging module, and then inputs it into the electric vehicle, and adjusts the output voltage and output current to the vehicle through real-time communication with the vehicle BMS.

What are the main components of the EV DC charger?

Charging module, main control board, communication board, man-machine interface, new energy charging gun, billing system, OCPP protocol, thermal treatment (liquid cooling or air cooling) , etc.

What is the bottleneck of the new energy electric vehicle industry?

The small number of new energy charging piles is one aspect, but the main bottleneck is short mileage, long charging time and high price;

short mileage is mainly due to the energy ratio and low energy density of the battery;

Low power ratio and power density; short life due to poor deep discharge capability;

High self-discharge, low charging sales; poor recyclability. The charging time is too long, mainly because there is no effective breakthrough in battery technology.

Post time: Sep-22-2022