Behind Next-gen Fast Charging: Smaller, Stronger, Smarter

July 18, 2025

Behind Next-gen Fast Charging: Smaller, Stronger, Smarter

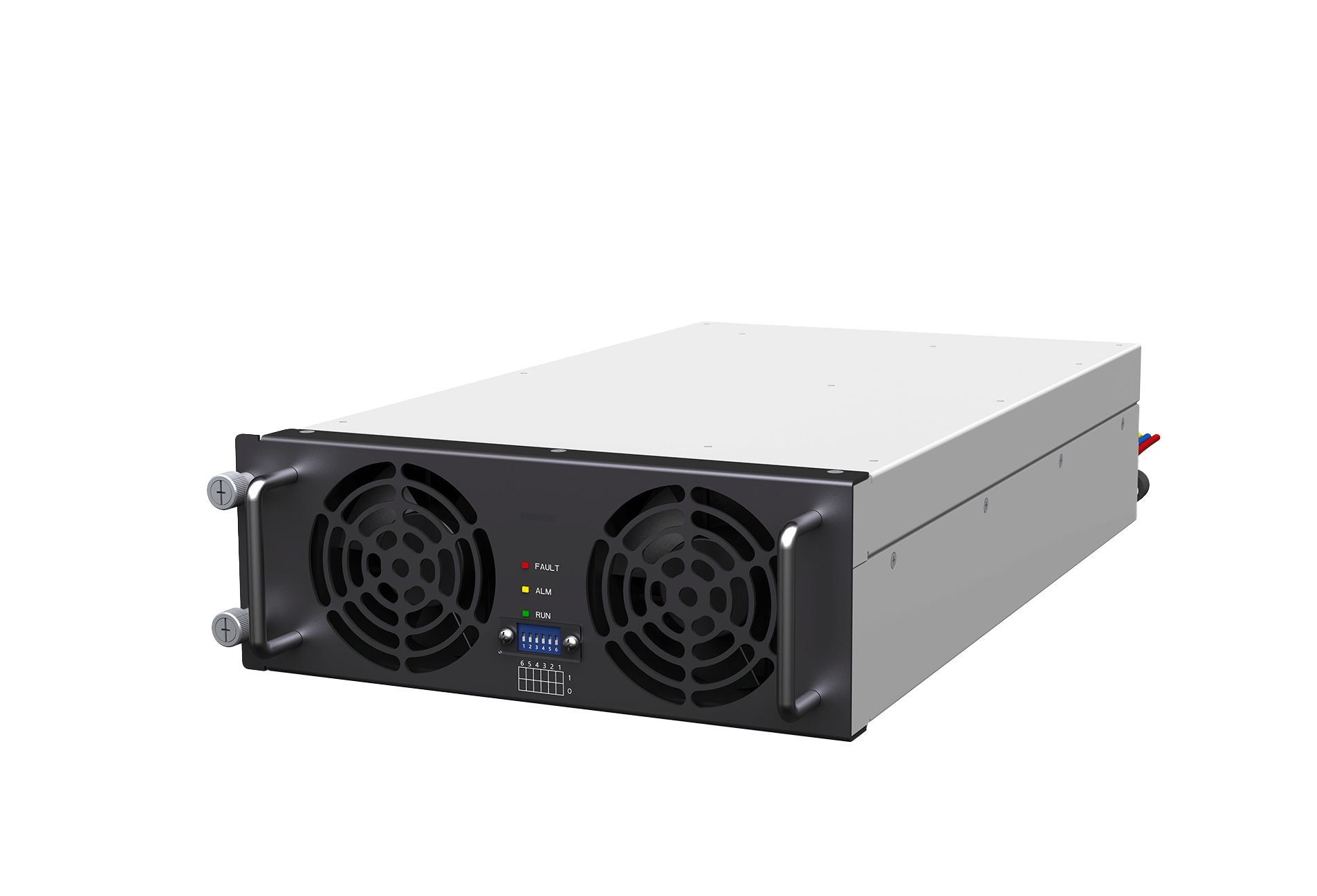

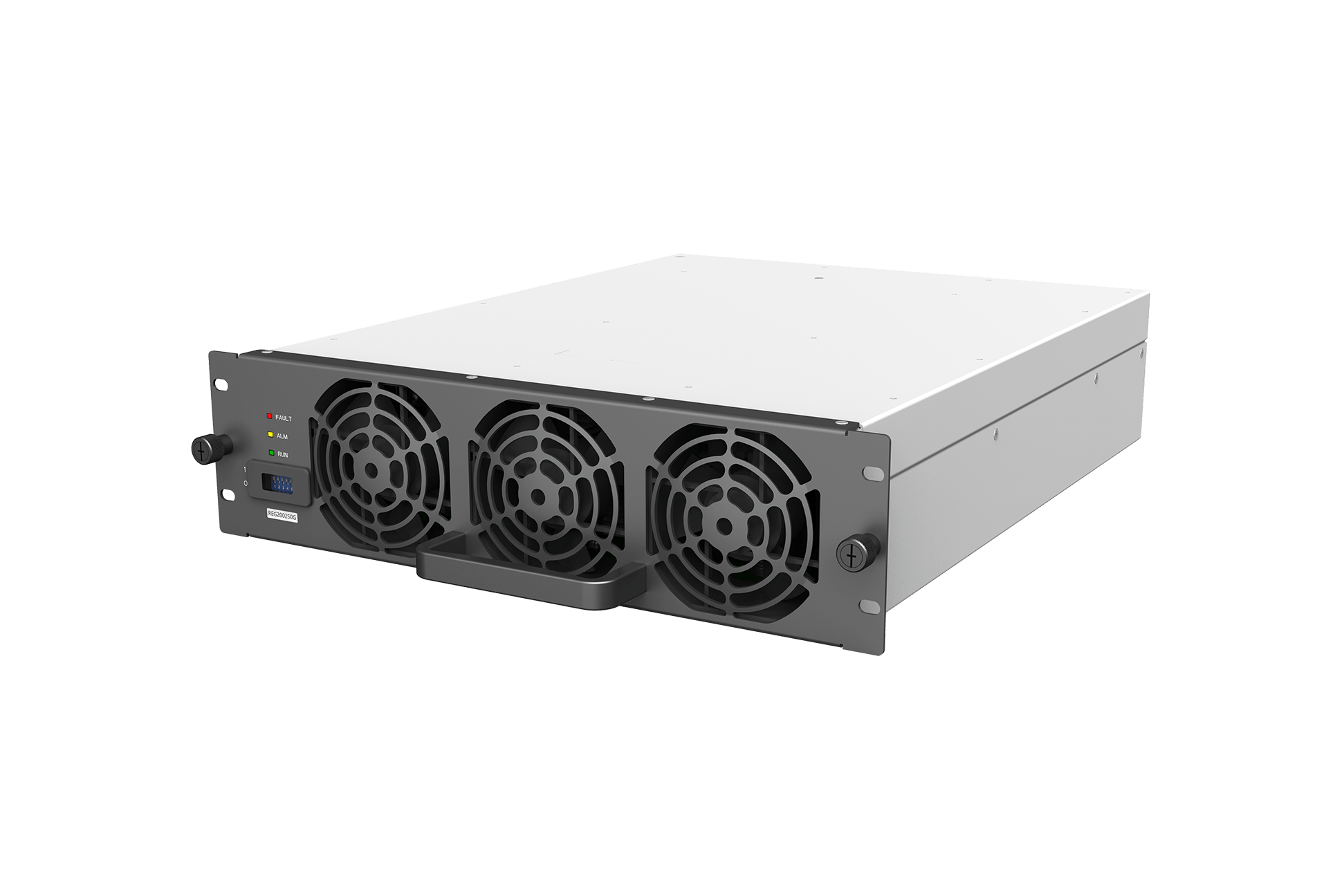

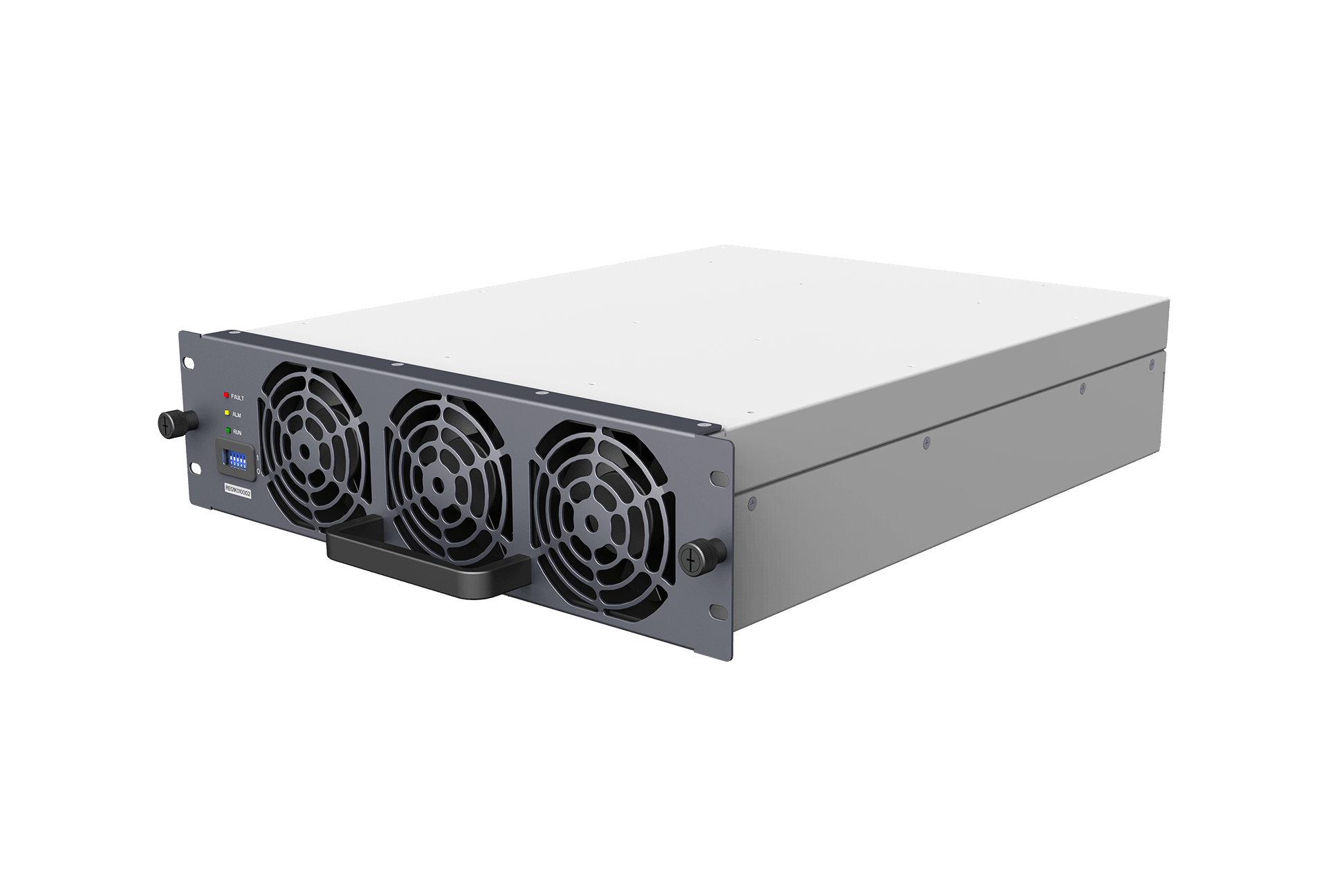

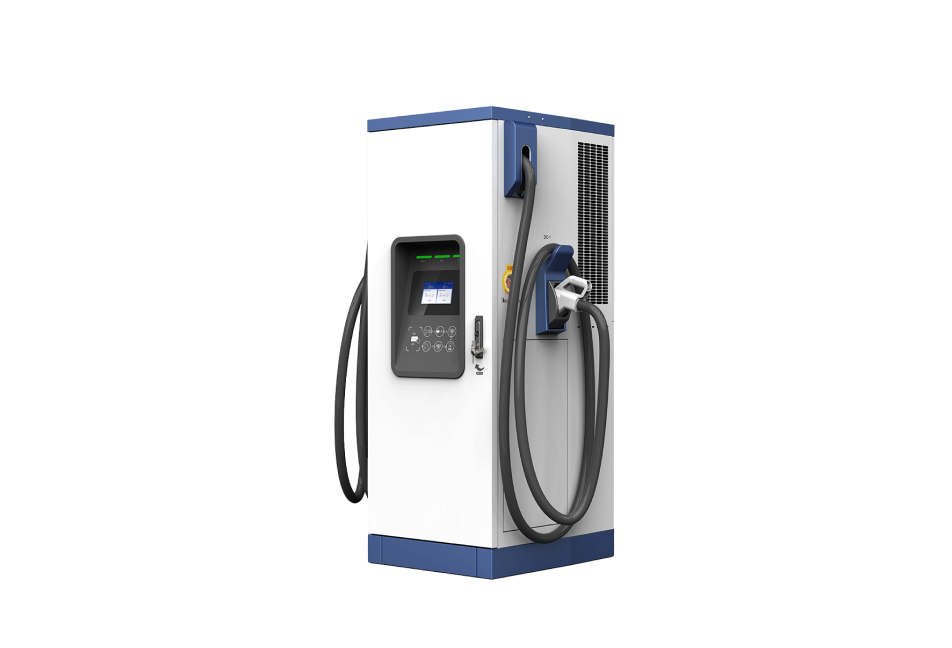

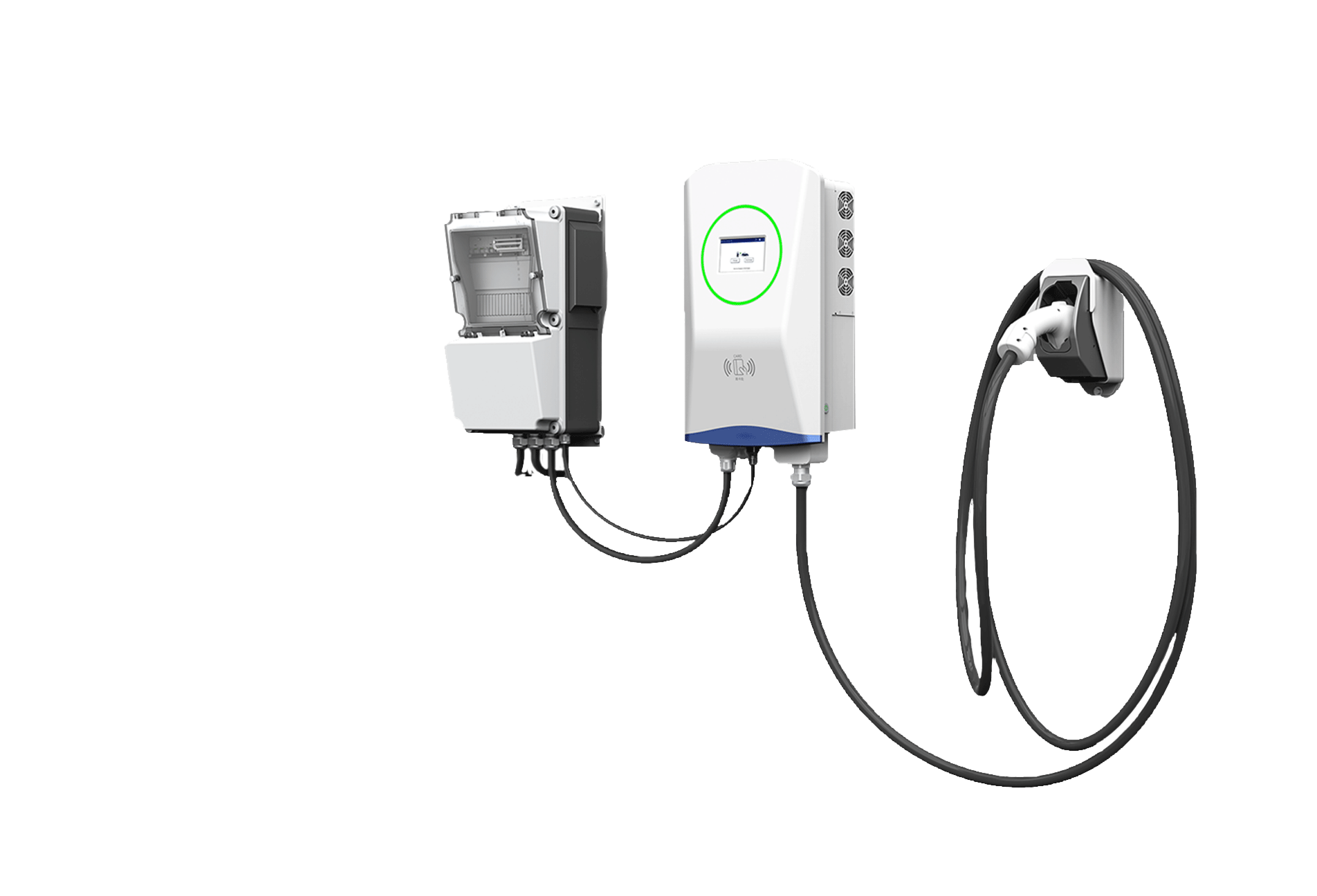

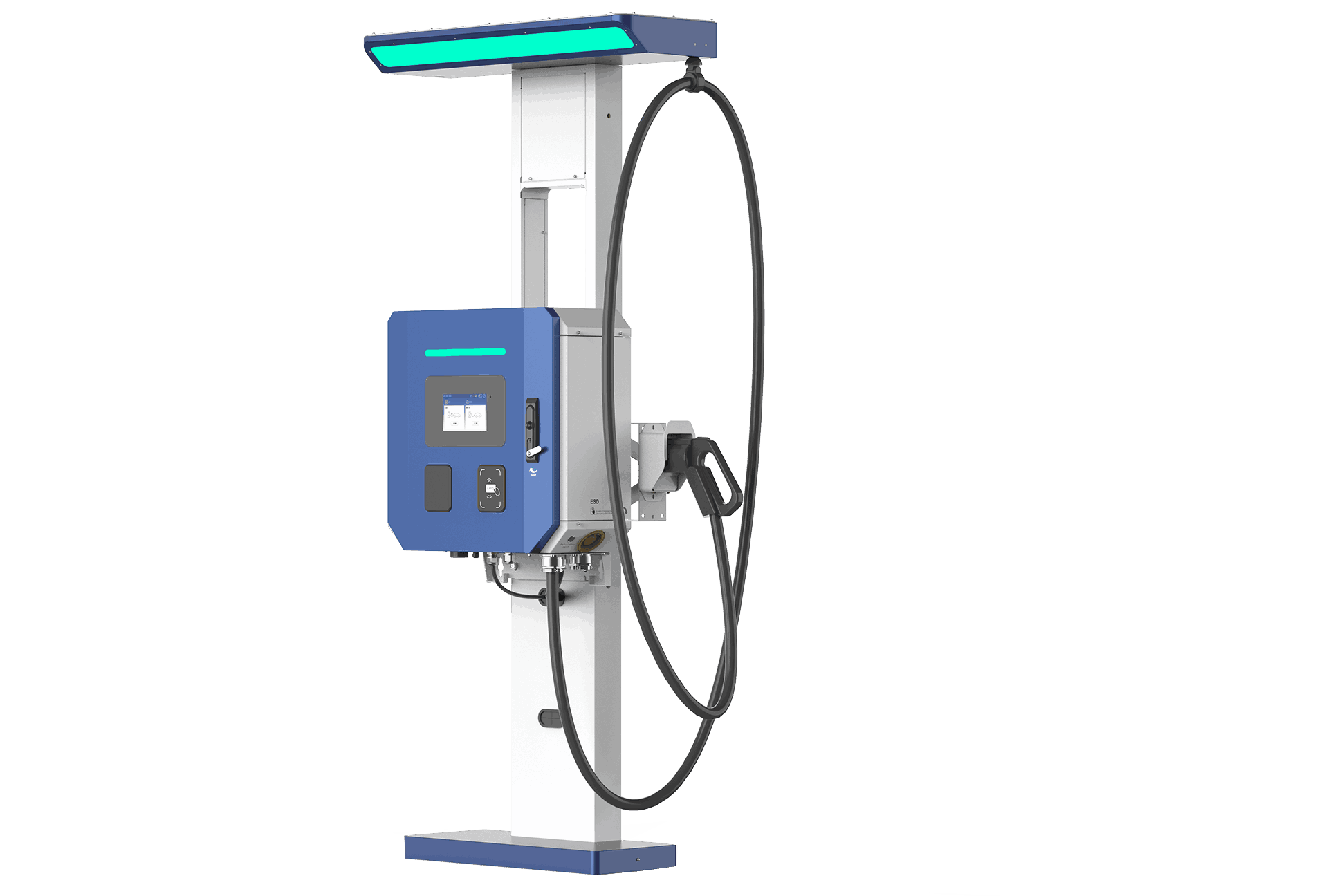

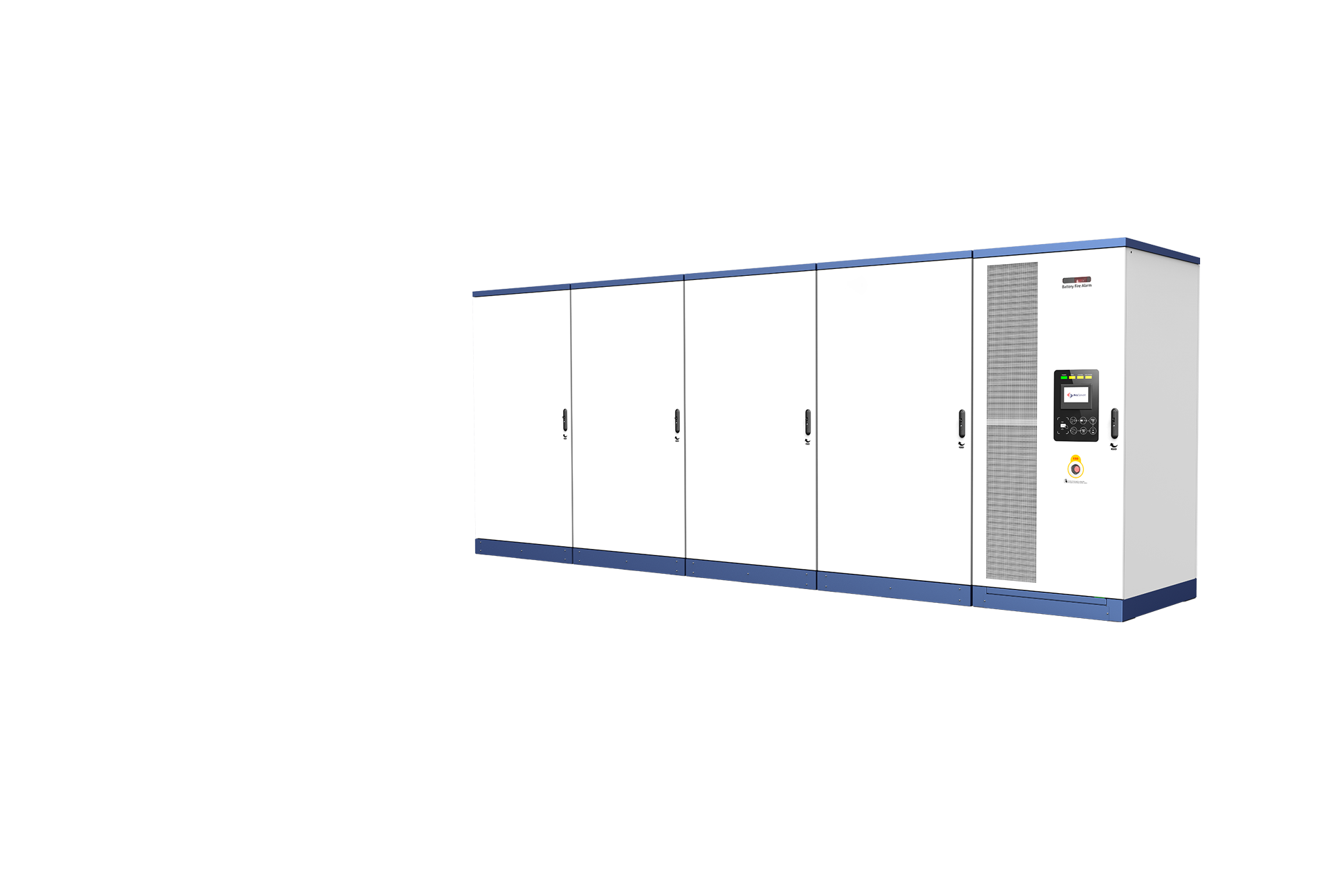

As modern DC fast charging networks advance to support shorter charging times, broader vehicle compatibility and smarter energy integration, focus is now being placed on the core technologies inside the charger. At the heart of every high-performance charging system is the power module, quietly responsible for how efficiently and reliably power flows from the grid to the vehicle. In next-gen HPC (High Power Charging) or MCS (Megawatt Charging System), power modules must do more than deliver kilowatts—they must do it smarter, more robustly and in more compact spaces.

Whether you're building a 160 kW+ fast charging station for urban EV fleets or scaling to 400 kW+ and megawatt systems for highway corridors, the power module inside directly influences your charger’s efficiency, thermal design, acoustic performance, and uptime. Leading HPC or MCS OEMs are looking not just for more power—but for power delivered intelligently, reliably and efficiently.

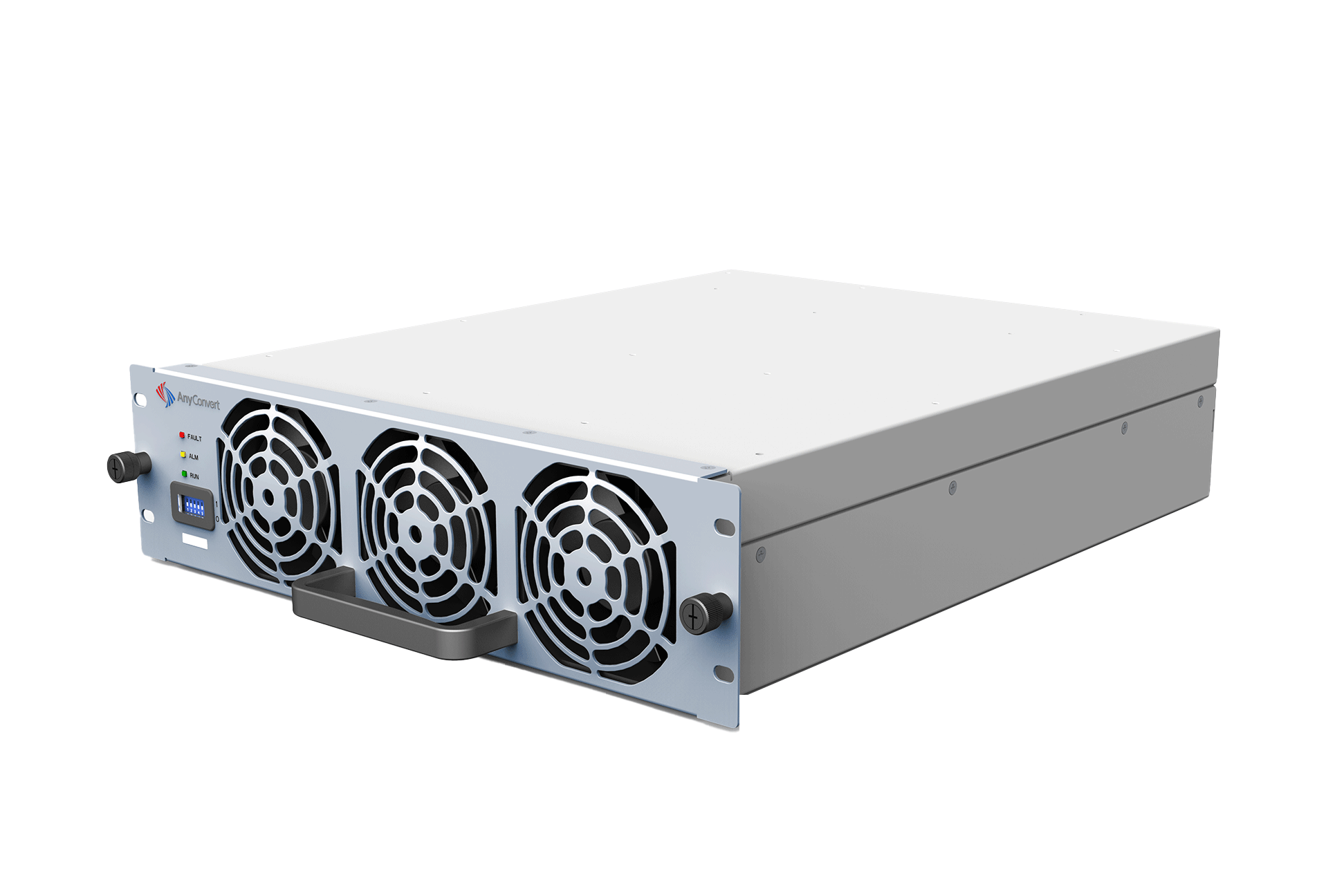

That’s exactly what our REG1K0135G2, the latest-generation DC charger module, was engineered to provide.

What Do DCFC (DC Fast Charger) OEMs Look for a Power Module?

Based on direct feedback from leading EV charger OEMs and CPOs worldwide, the following power module features are consistently ranked as top priorities:

✅ High Power Density

More kilowatts per cubic inch means a smaller system footprint and more efficient use of cabinet space. A power module with high power density reduces the overall size and weight of the charger, simplifying installation and enabling deployment in space-constrained urban or roadside environments.

✅ High Conversion Efficiency

Every percentage point of efficiency gained reduces energy losses and heat generation—critical for improving thermal design, meeting global regulatory standards (e.g., EU CoC, U.S. DoE), and lowering total cost of ownership (TCO). In large-scale deployments, every efficiency improvement translates into significant long-term savings.

✅ Low Noise

Power modules with reduced acoustic and electromagnetic emissions enhance the end-user experience and simplify EMC compliance. This is particularly important in high-traffic locations, residential areas, or transit hubs where noise and interference constraints are stricter.

✅ High Reliability

Power module reliability directly impacts charger uptime, maintenance cycles, and end-user confidence. In public charging networks, where downtime leads to lost revenue and degraded brand perception, module-level reliability becomes a mission-critical metric.

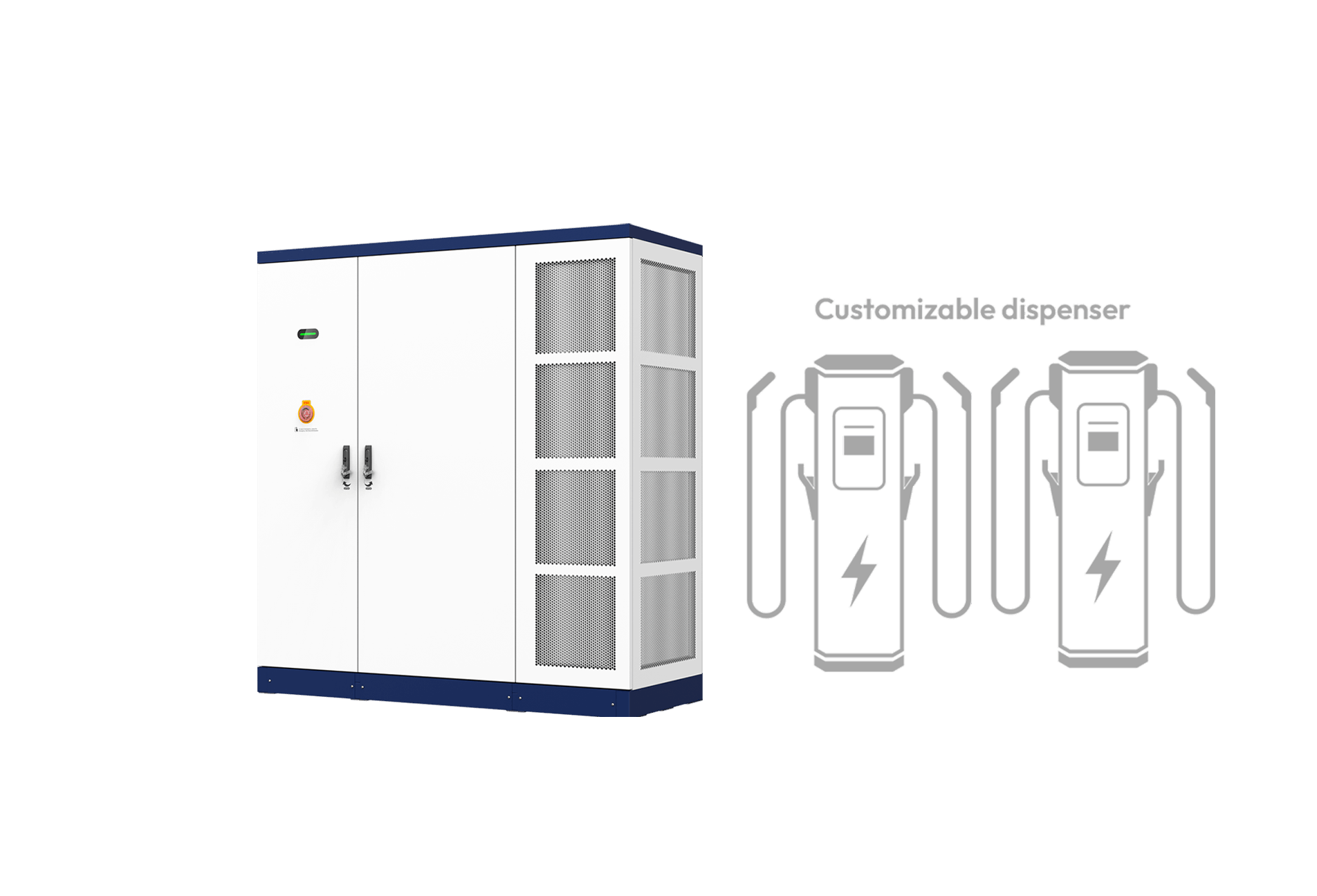

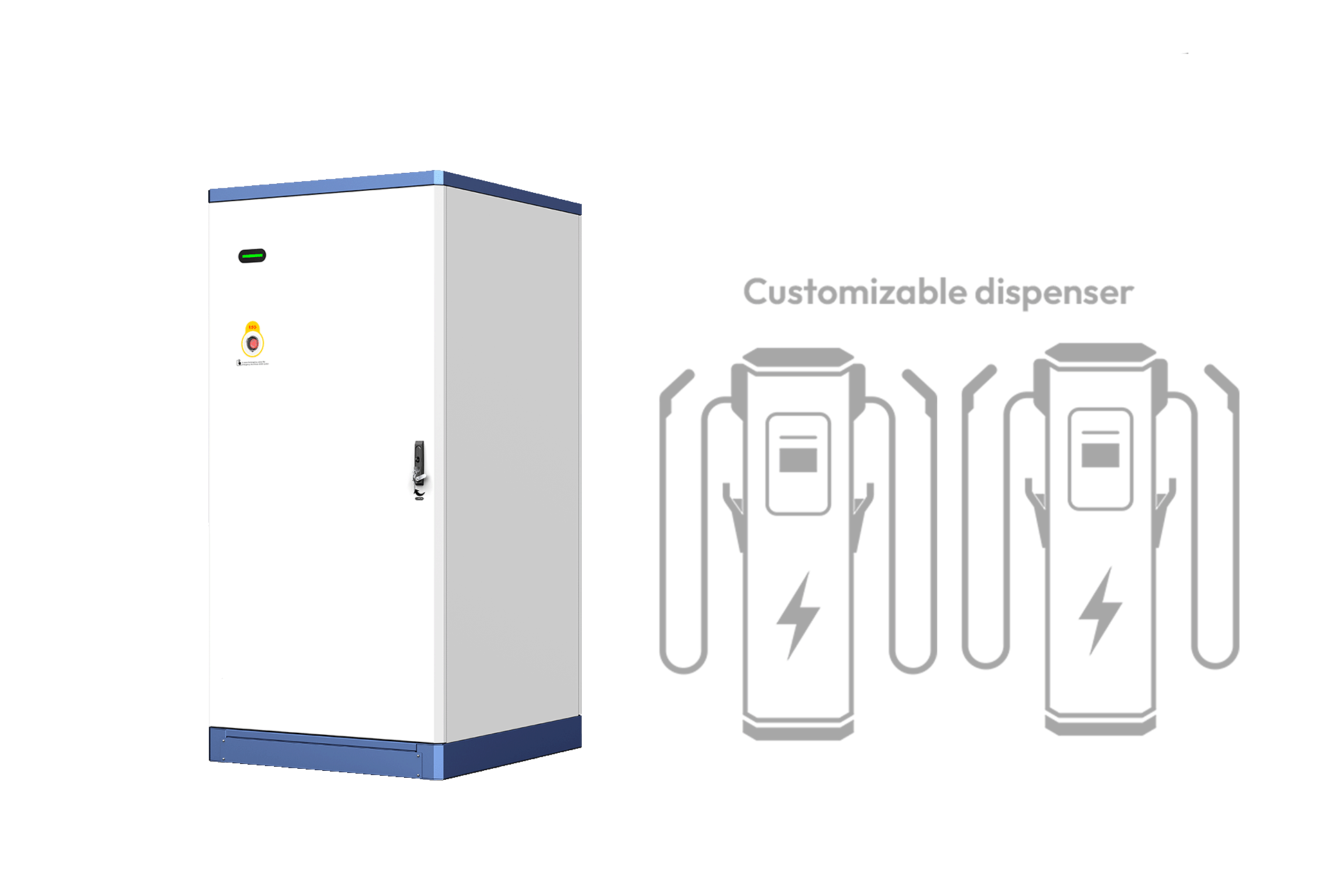

✅ Smart Modularity

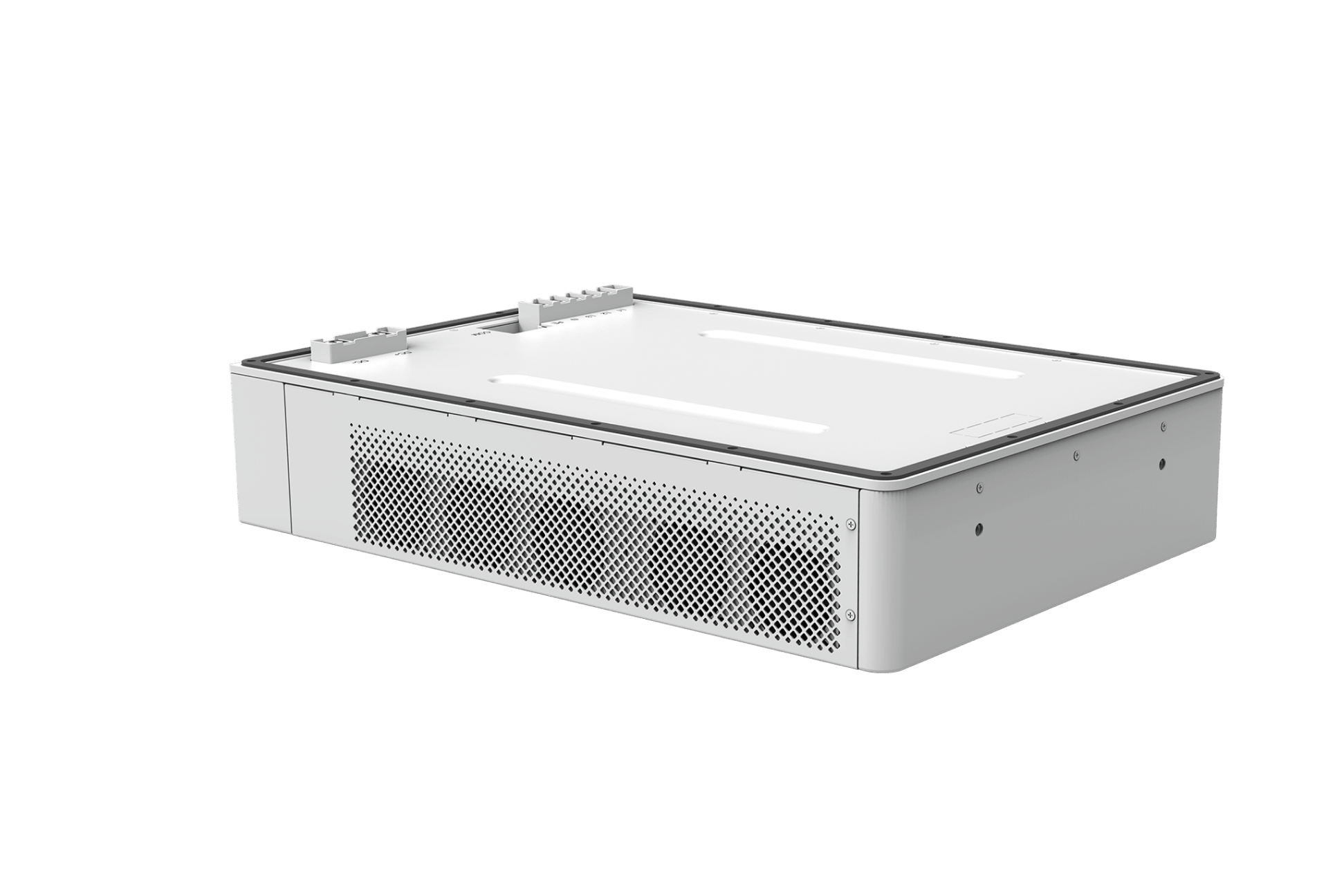

Modular architecture with hot-swappable and stackable design enables flexible power scaling, streamlined serviceability, and faster fault isolation. This reduces system downtime and supports high-availability charger designs, which are increasingly required by fleet operators and infrastructure providers.

Technology Deep Dive: What Makes Our REG1K0135G2 Different?

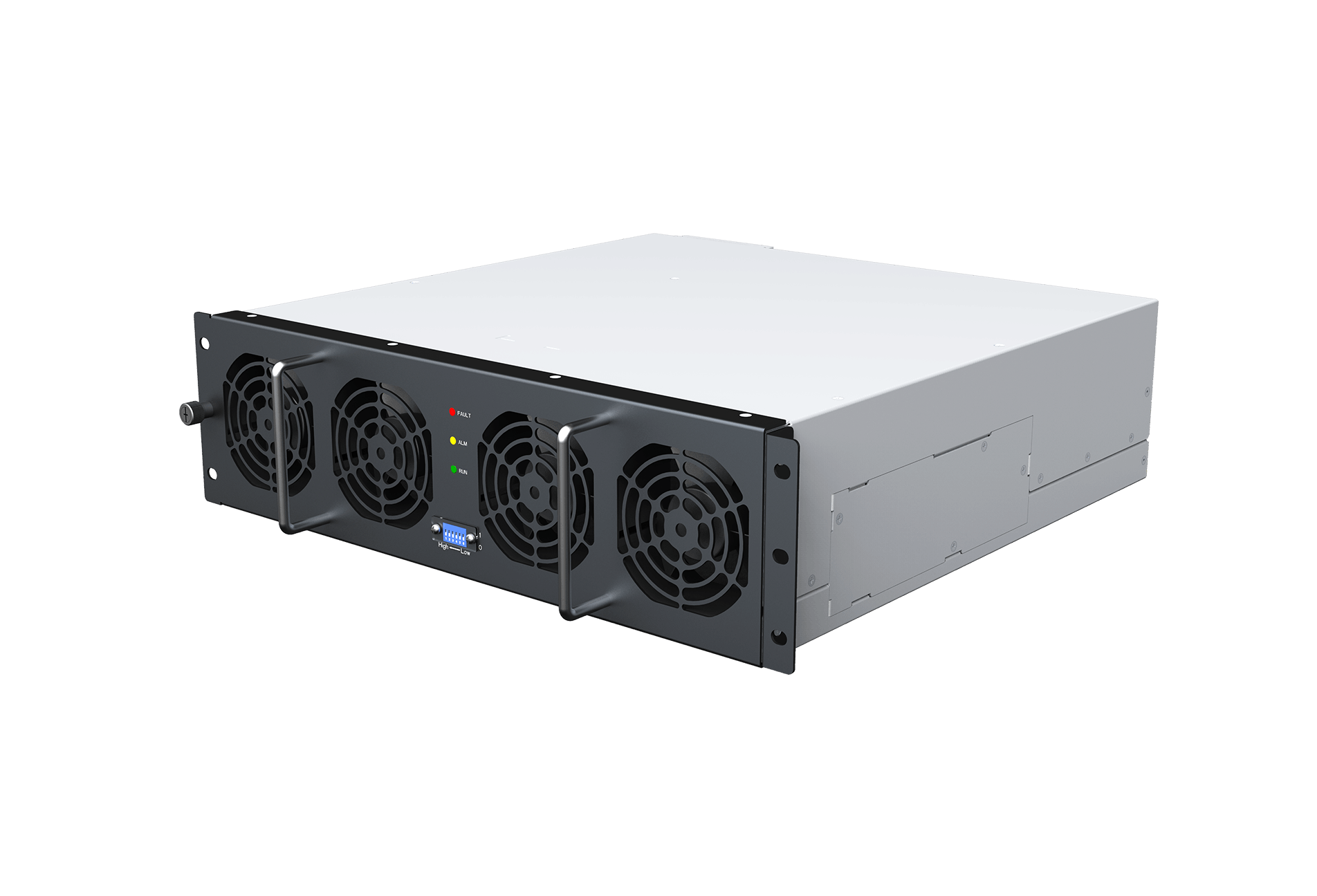

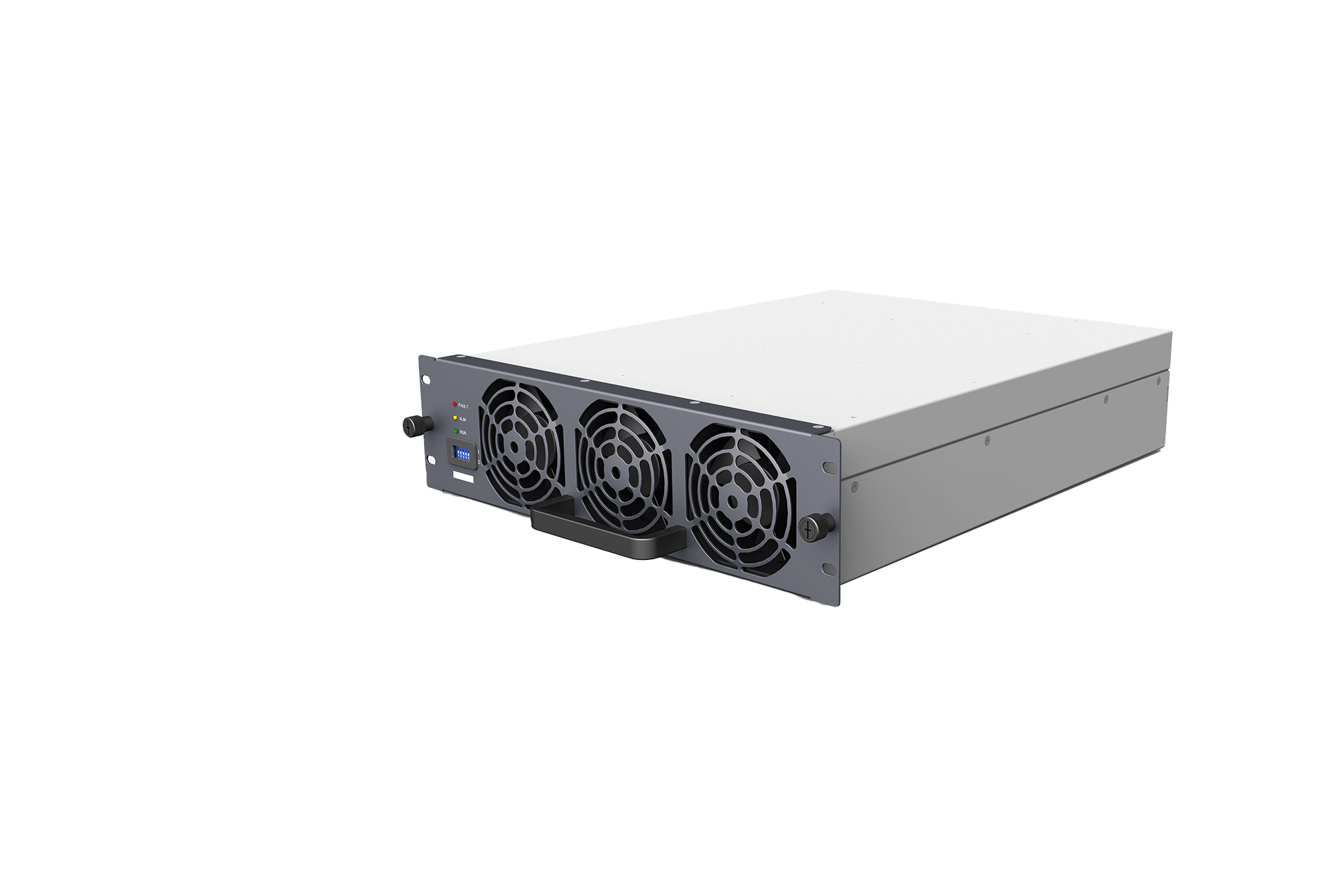

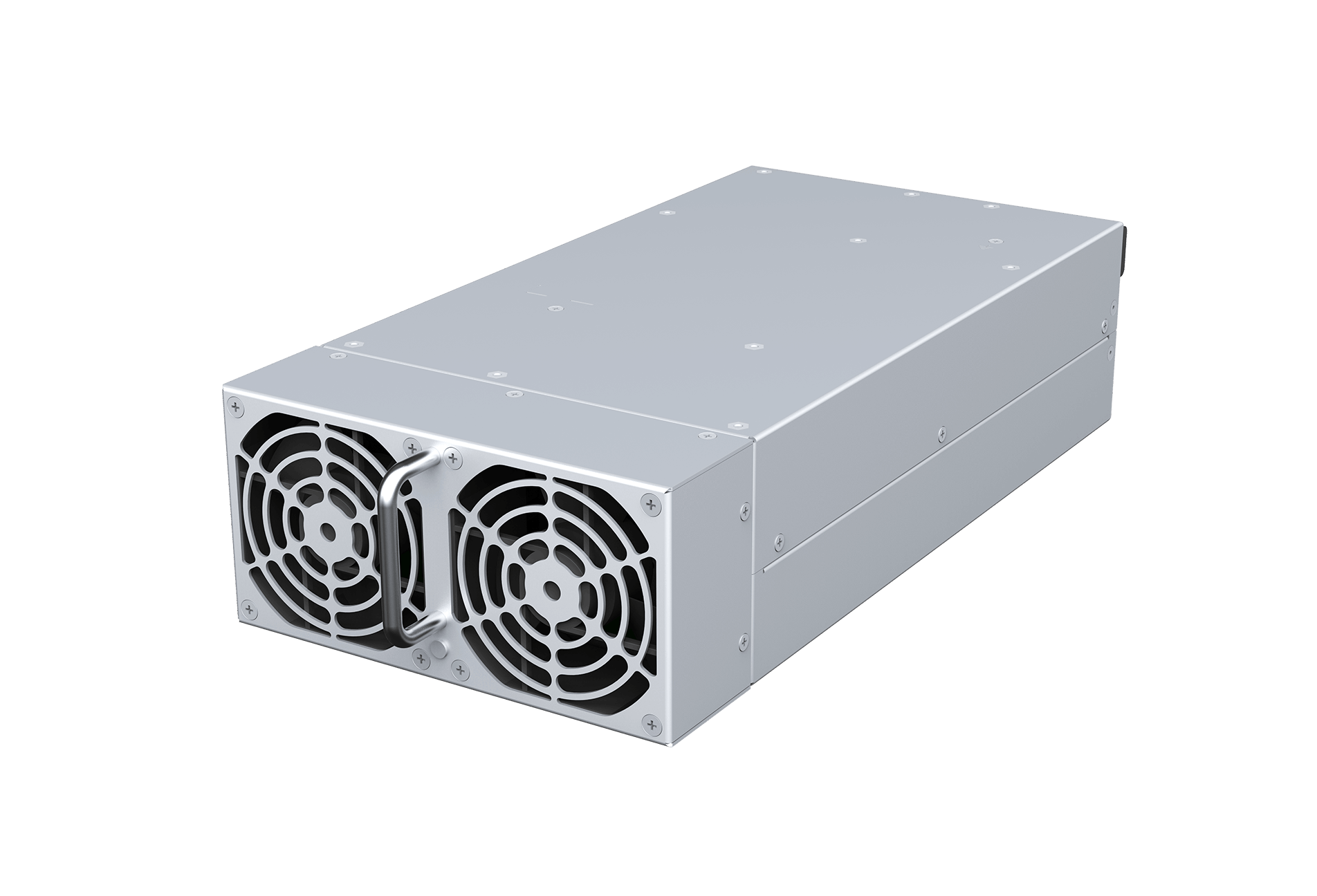

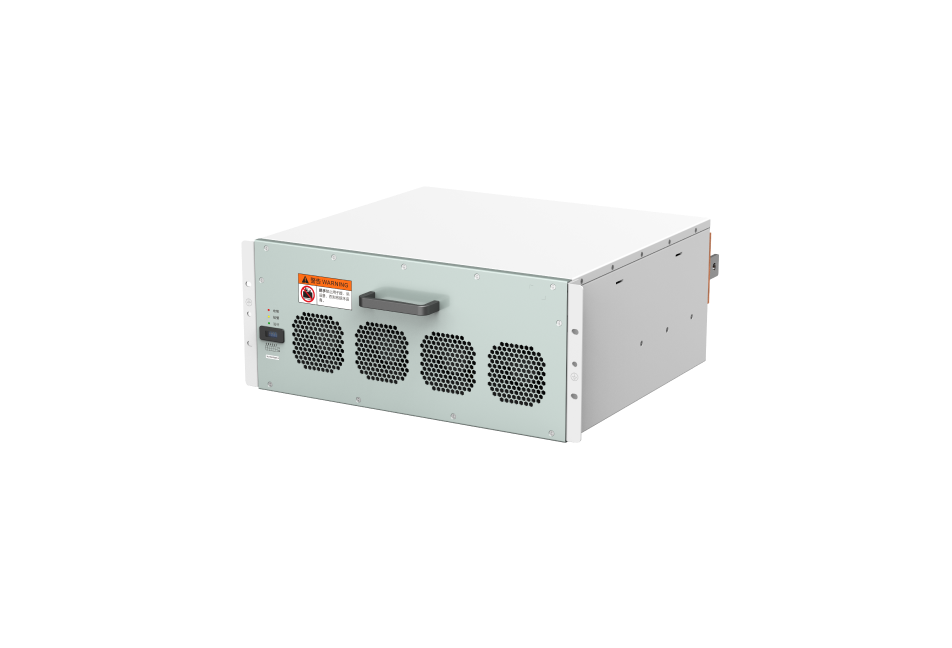

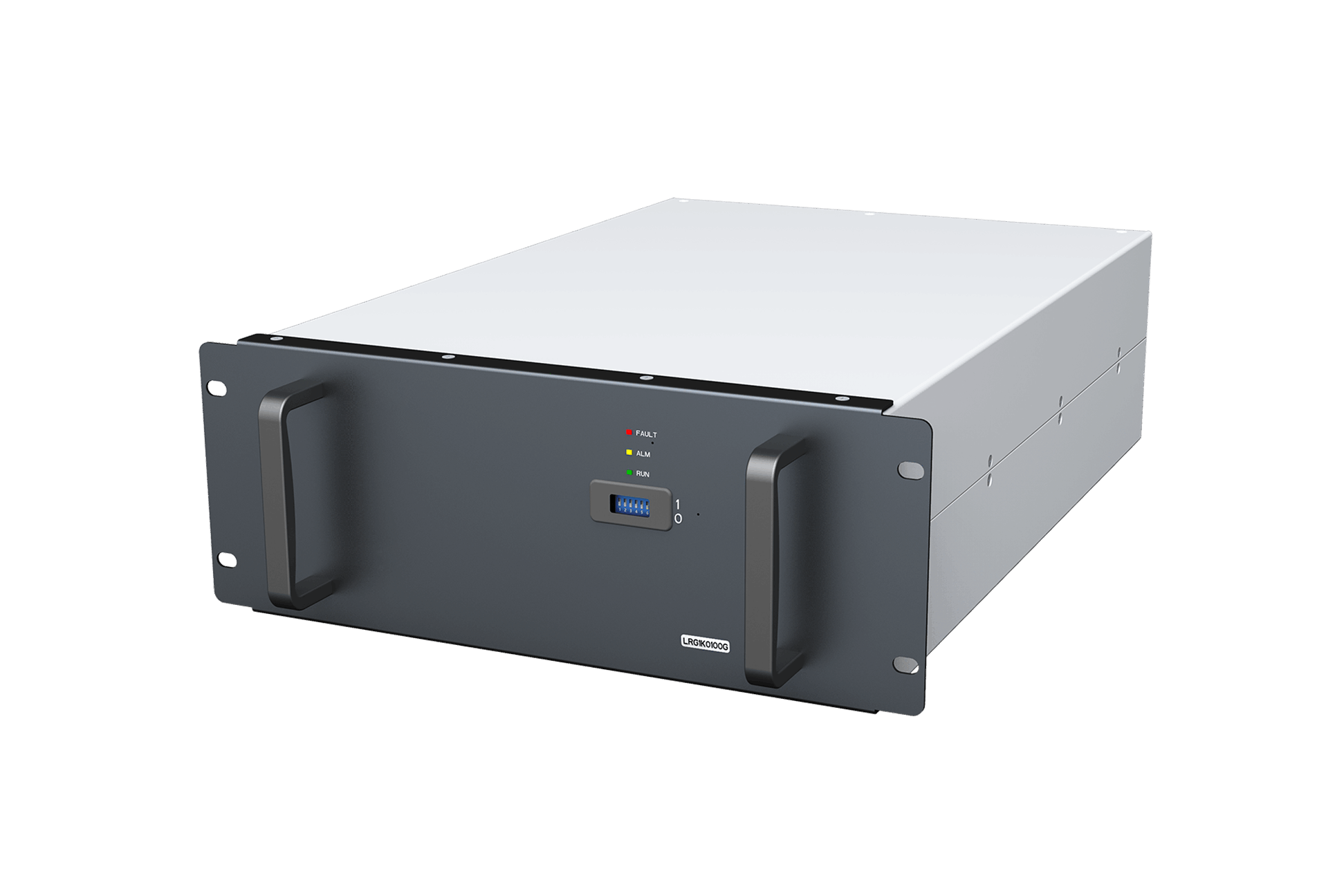

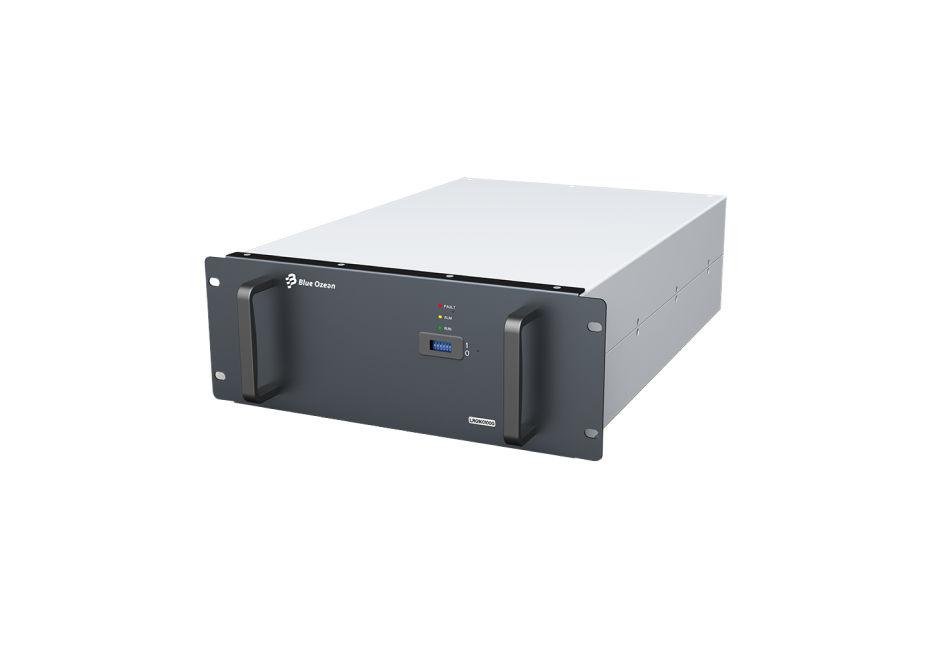

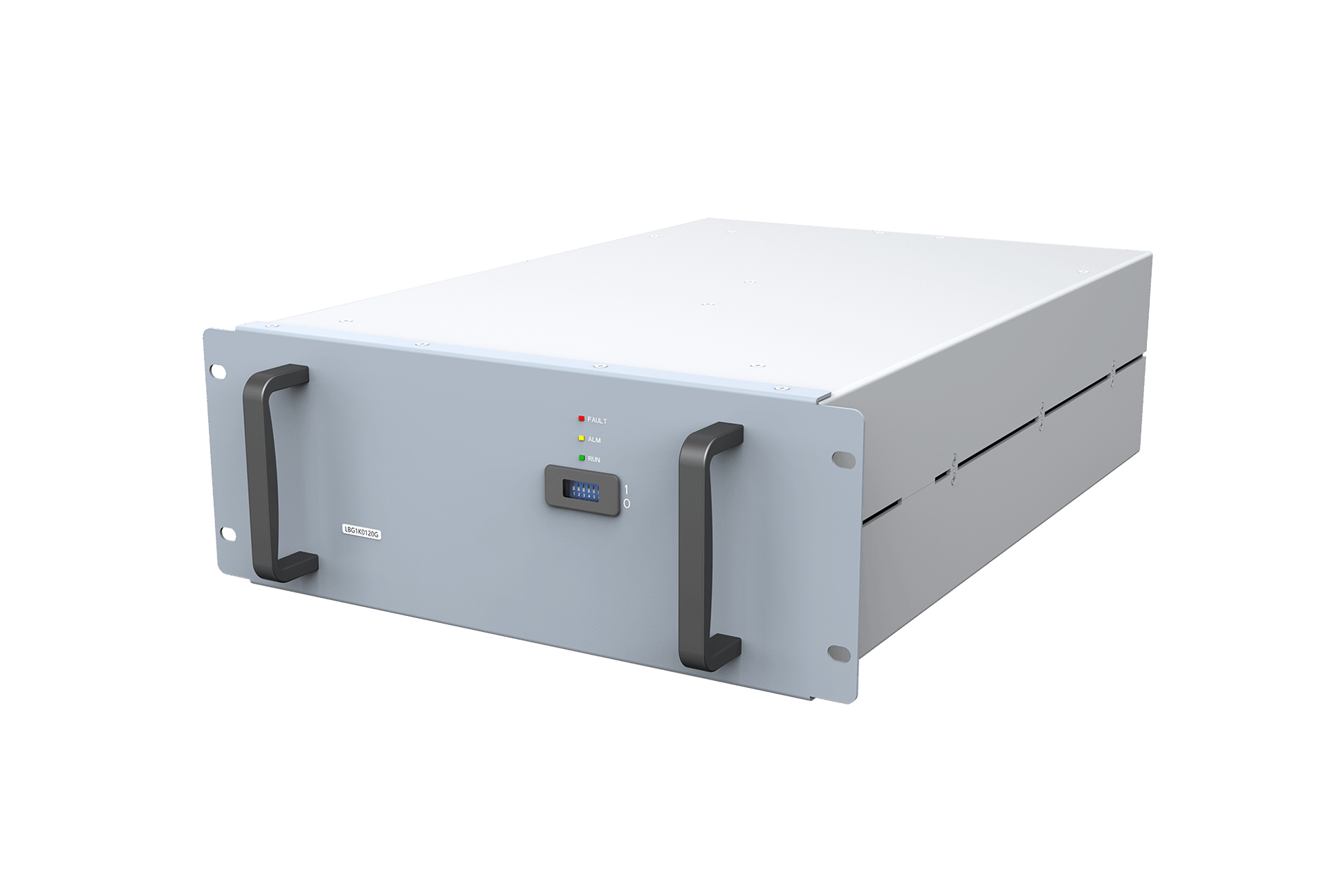

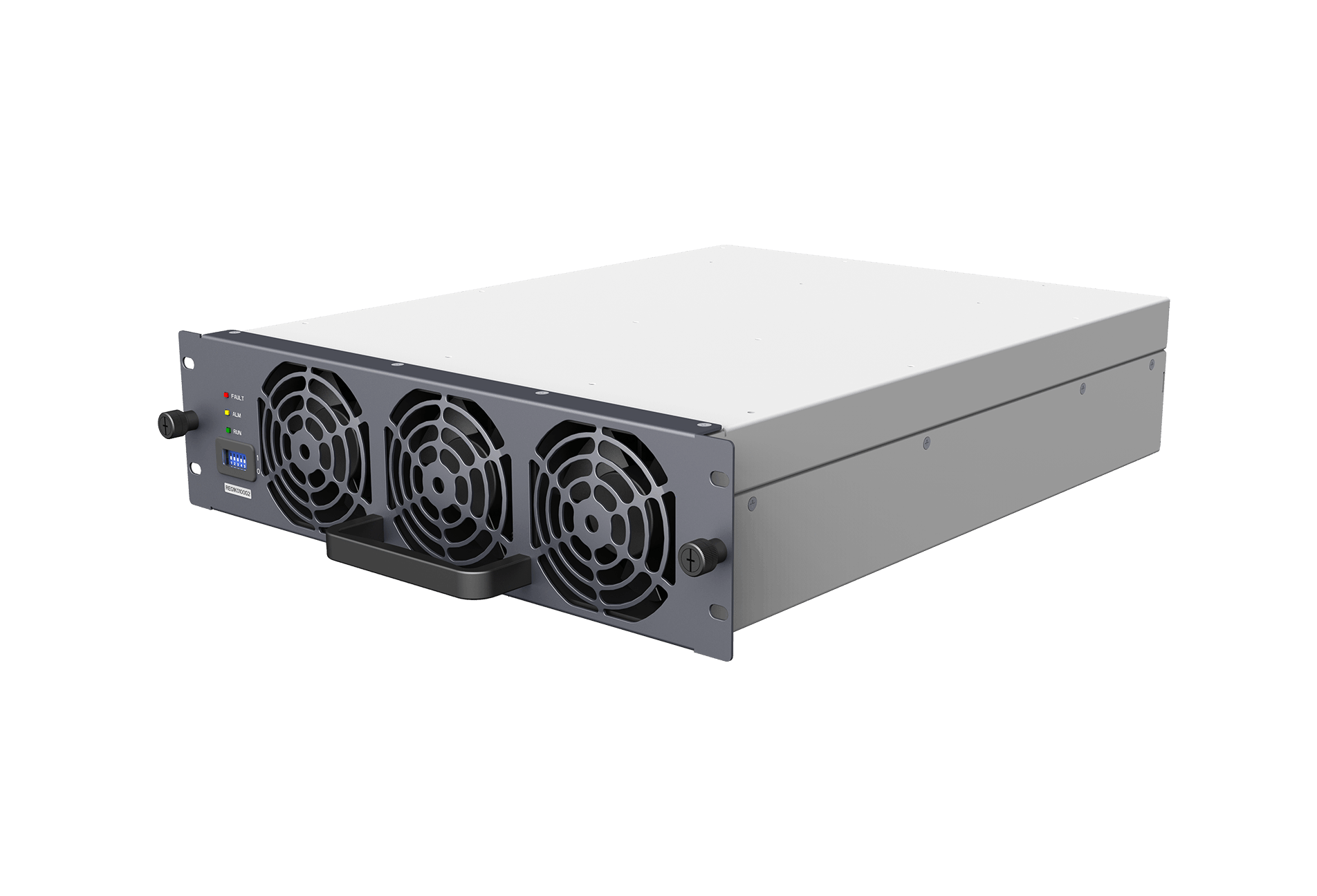

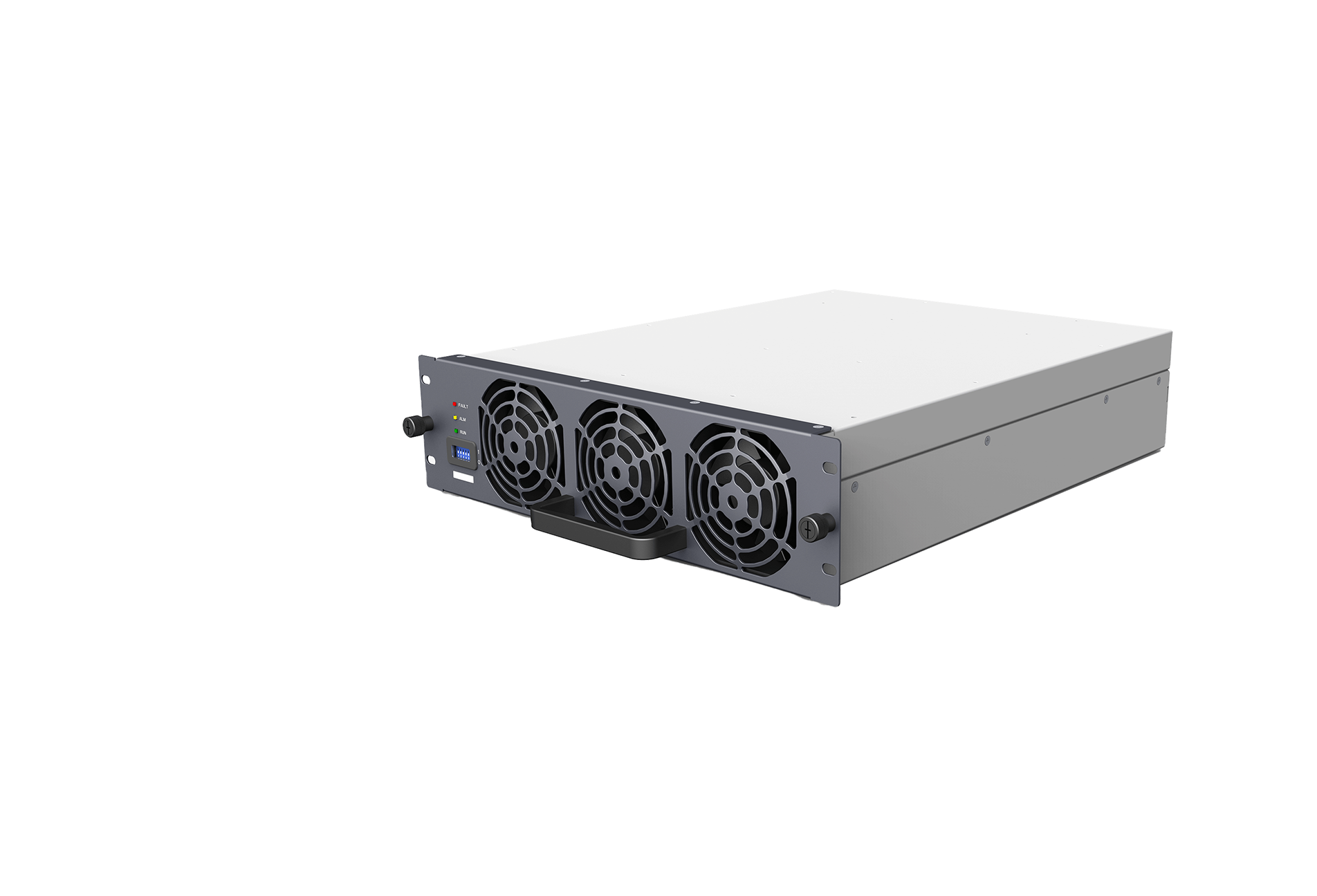

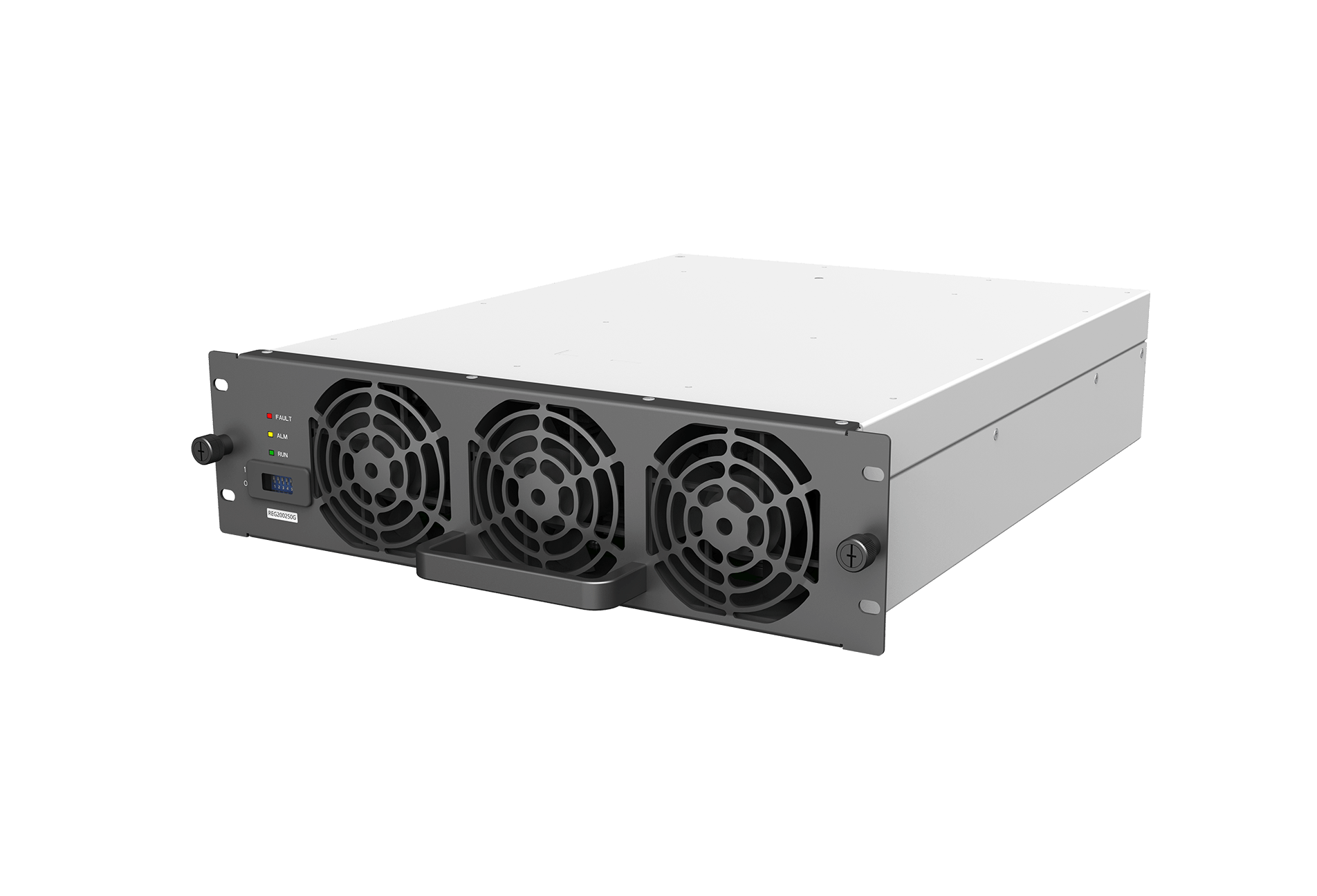

The REG1K0135G2, Infypower G2 40kW 1000V AC/DC Power Module, is engineered to simplify system integration and accelerate time-to-market for next-generation fast charging platforms. Its mechanical compatibility with other G2 modules (DC/DC, BiDi DC/DC, BiDi AC/DC, VPF) allows developers to design around a unified platform across multiple applications—reducing engineering complexity, shortening design cycles, and maximizing BOM flexibility.

For DC charger OEMs building 150 kW to MW systems, its cross-compatibility is vital. It helps reduce cabinet redesigns when scaling from unidirectional to bidirectional systems, or when adapting to different grid or vehicle-side configurations.

1. Patented Topology + Full SiC Design

Three-phase half-bridge circuit doubles inductor current frequency, reducing ripple and switching losses.

Patented in-house combination switch achieves low conduction losses and high conversion efficiency. It supports nanosecond-level switching while ensuring uninterrupted power output during transitions.

Patented double-layer main transformer skeleton physically separates the primary and secondary windings. This not only increases heat dissipation channels but also enlarges electrical distance.

Full SiC design can lower switching and conduction losses, while providing higher switching frequency and better thermal performance.

2. Wide Constant Power Output Range

It delivers constant power from 300 V to 1000 V DC, suitable for both passenger vehicles and commercial fleets.

It maintains high current output (e.g., 133.3 A down to 50 V), enabling compatibility with low-voltage fast-charging requirements.

3. Power Density > 65 W/in³

Its industry highest power density makes it possible to significantly saves cabinet space and simplifies mechanical layout for highly integrated HPC or MCS systems.

4. Peak Efficiency ≥97.5%

This significantly reduces heat generation and improves overall system energy utilization. With the full-load efficiency over 96.5%, it’s truly energy saving and environmentally friendly.

5. Low Reactive Power

High power factor performance during standard charging process (No load PF >0.9, full-load PF ≥0.99).

Minimizes grid disturbance and improves overall system efficiency in DC charging.

6. ESTOP, 1ms Shutdown

Rapid shutdown response for enhanced system safety and protection in any emergency.

7. Low Noise <55dB (Silent Mode)

Standard, de-noise and silent modes can be set, helping meet different regulatory and site-level requirements. Low acoustic noise makes it ideal for deployment in noise-sensitive sites.

8. Normal Operation from -40°C to 55°C

Exceptional module thermal adaptability makes the system ready for diverse geographies, from Nordic winters to Middle Eastern summers, without the need for excessive system thermal control. Above 55°C, derating mechanisms apply.

Ready for Your Next Charger Platform?

If you are developing next-generation HPC or MCS platforms, REG1K0135G2 is designed to be the core building block—delivering unrivaled efficiency and reliability that modern fast charging demands.

Connect with us to discuss how our power modules can enhance your charger architecture—from design to deployment.